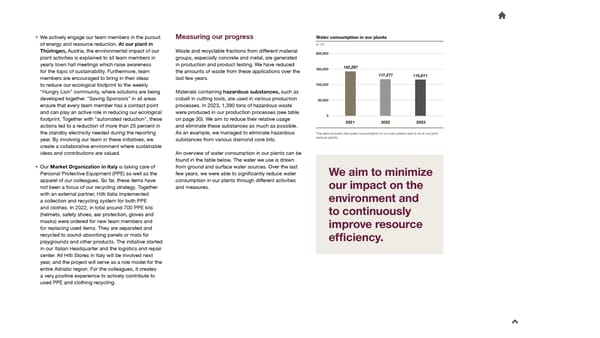

• We actively engage our team members in the pursuit Measuring our progress Water consumption in our plants of energy and resource reduction. At our plant in in m3 Thüringen, Austria, the environmental impact of our Waste and recyclable fractions from different material 200,000 plant activities is explained to all team members in groups, especially concrete and metal, are generated yearly town hall meetings which raise awareness in production and product testing. We have reduced 150,000 142,287 for the topic of sustainability. Furthermore, team the amounts of waste from these applications over the 117,277 115,971 members are encouraged to bring in their ideas last few years. to reduce our ecological footprint to the weekly 100,000 “Hungry Lion” community, where solutions are being Materials containing hazardous substances, such as developed together. “Saving Sponsors” in all areas cobalt in cutting tools, are used in various production 50,000 ensure that every team member has a contact point processes. In 2023, 1,390 tons of hazardous waste and can play an active role in reducing our ecological were produced in our production processes (see table 0 footprint. Together with “automated reduction”, these on page 30). We aim to reduce their relative usage 2021 2022 2023 actions led to a reduction of more than 25 percent in and eliminate these substances as much as possible. the standby electricity needed during the reporting As an example, we managed to eliminate hazardous The data includes the water consumption in our own plants and in all of our joint year. By involving our team in these initiatives, we substances from various diamond core bits. venture plants. create a collaborative environment where sustainable ideas and contributions are valued. An overview of water consumption in our plants can be found in the table below. The water we use is drawn • Our Market Organization in Italy is taking care of from ground and surface water sources. Over the last Personal Protective Equipment (PPE) as well as the few years, we were able to signi昀椀cantly reduce water We aim to minimize apparel of our colleagues. So far, these items have consumption in our plants through different activities not been a focus of our recycling strategy. Together and measures. our impact on the with an external partner, Hilti Italia implemented environment and a collection and recycling system for both PPE and clothes. In 2022, in total around 700 PPE kits to continuously (helmets, safety shoes, ear protection, gloves and masks) were ordered for new team members and improve resource for replacing used items. They are separated and recycled to sound-absorbing panels or mats for playgrounds and other products. The initiative started ef昀椀ciency. in our Italian Headquarter and the logistics and repair center. All Hilti Stores in Italy will be involved next year, and the project will serve as a role model for the entire Adriatic region. For the colleagues, it creates a very positive experience to actively contribute to used PPE and clothing recycling.

2023 Sustainability Report Page 28 Page 30

2023 Sustainability Report Page 28 Page 30